Ductility in Structures

In construction engineering, ductility describes the extent to which a material (or structure) can undergo large deformations without failing. Inelastic energy dissipation plays an important role in resisting earthquakes.

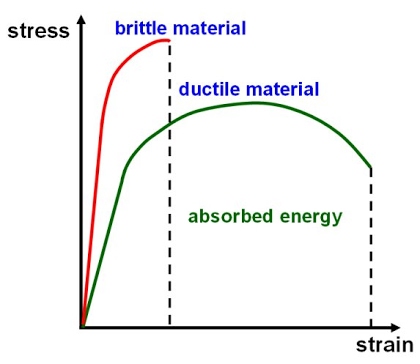

Inelasticity in materials generate large strains and large strains corresponds to larger deformations. Elastic deformations of material result in very low energy dissipation while the inelastic zone of the stress strain curve helps in much more dissipation of energy. Inelasticity results in very high strains and so it is important that the member is ductile, why? Because ductility is the ability of the material to go under large strains means a material that is more ductile can go into inelastic zones and can dissipate a lot of energy.

So, how do we make sure that we are achieving sufficient ductility for the structure? Here is the answer, the ductility of the structure is hidden inside its detailing. A well detailed structure will lead to a better performance under earthquakes as conpared to a poorly detailed one. Structures are generally made of two primary materials concrete and steel. We know that steel is very ductile, but concrete is not much.

So, how can we make concrete and steel structures ductile? We make conceret structures ductile by adding sufficient steel into concrete members. And we make steel structures more ductile by making connection stronger than the member itself. Also we make a structure more ductile by making columns stronger than beams so that columns remain elastic in case of earthquakes.